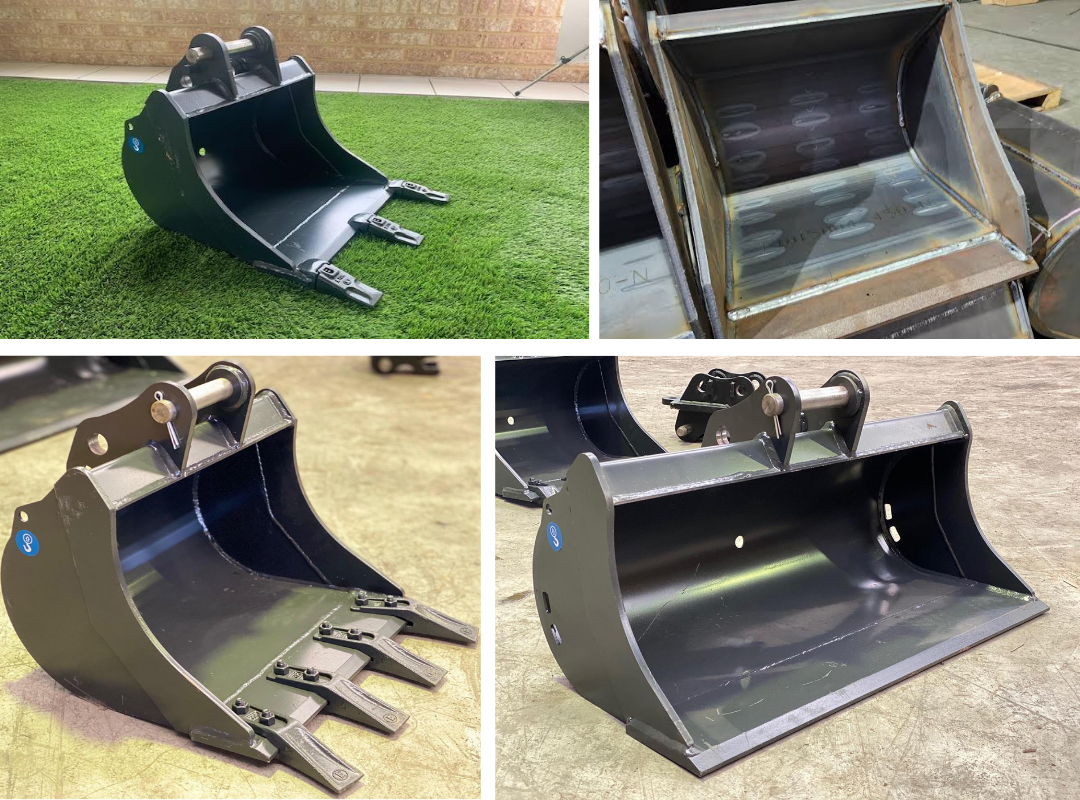

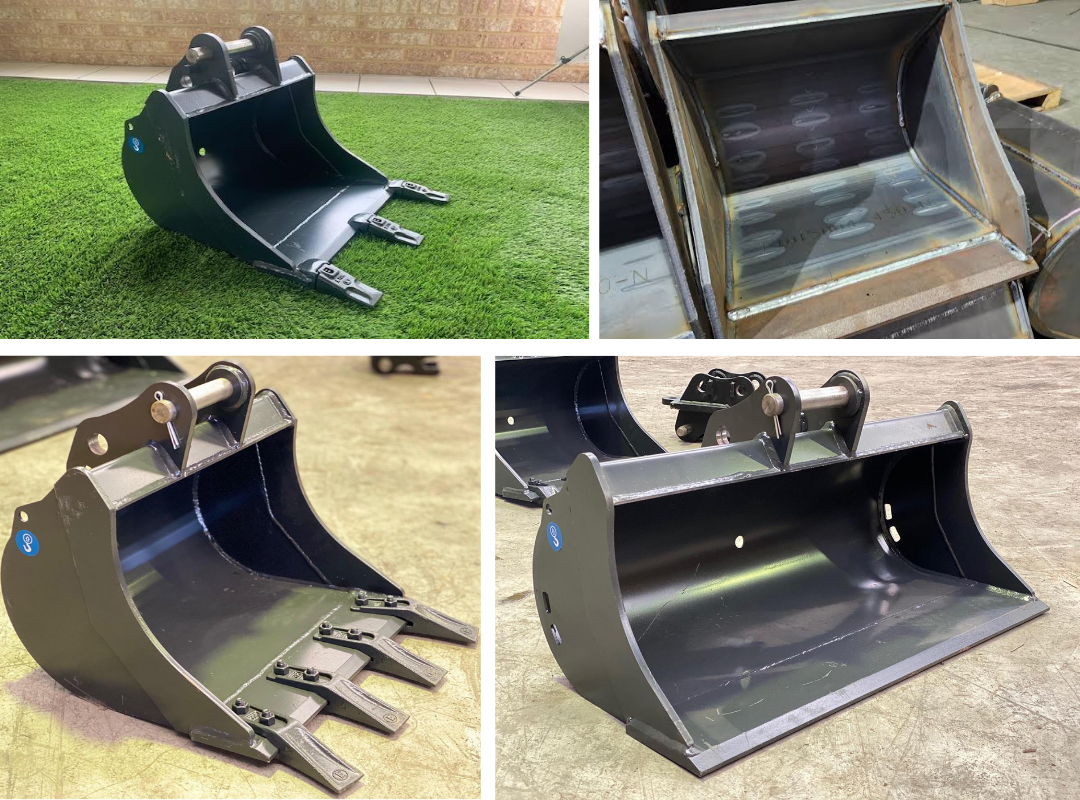

Our excavator bucket production is the result of years of engineering expertise, innovative design, and cutting-edge technology. With a team of skilled professionals and extensive industry knowledge, we are launching the production of manual buckets, with a planned expansion to hydraulic models, to meet the demands of modern construction and market needs.

Each bucket and attachment are precisely designed for maximum durability, high efficiency, and top performance, helping to increase productivity and reduce operating costs on construction sites.

We are currently in the process of modeling and manufacturing casting molds to start the production of excavator bucket teeth from alloy steel castings according to EN 10293 (G20Mn5, GX120Mn12). These materials offer a balanced combination of wear and impact resistance, with a hardness of 250–350 HBW, tensile strength of 725–1050 MPa, yield strength of 450–650 MPa, and elongation of 10–15%, ensuring durability and reliability in the most demanding operating conditions.

By utilizing advanced metallurgical processes and state-of-the-art manufacturing techniques, we ensure that our products meet the highest industry standards. Our combination of expertise, precision, and commitment to quality guarantees robust and reliable solutions that enhance excavation efficiency and all types of earthmoving operations.

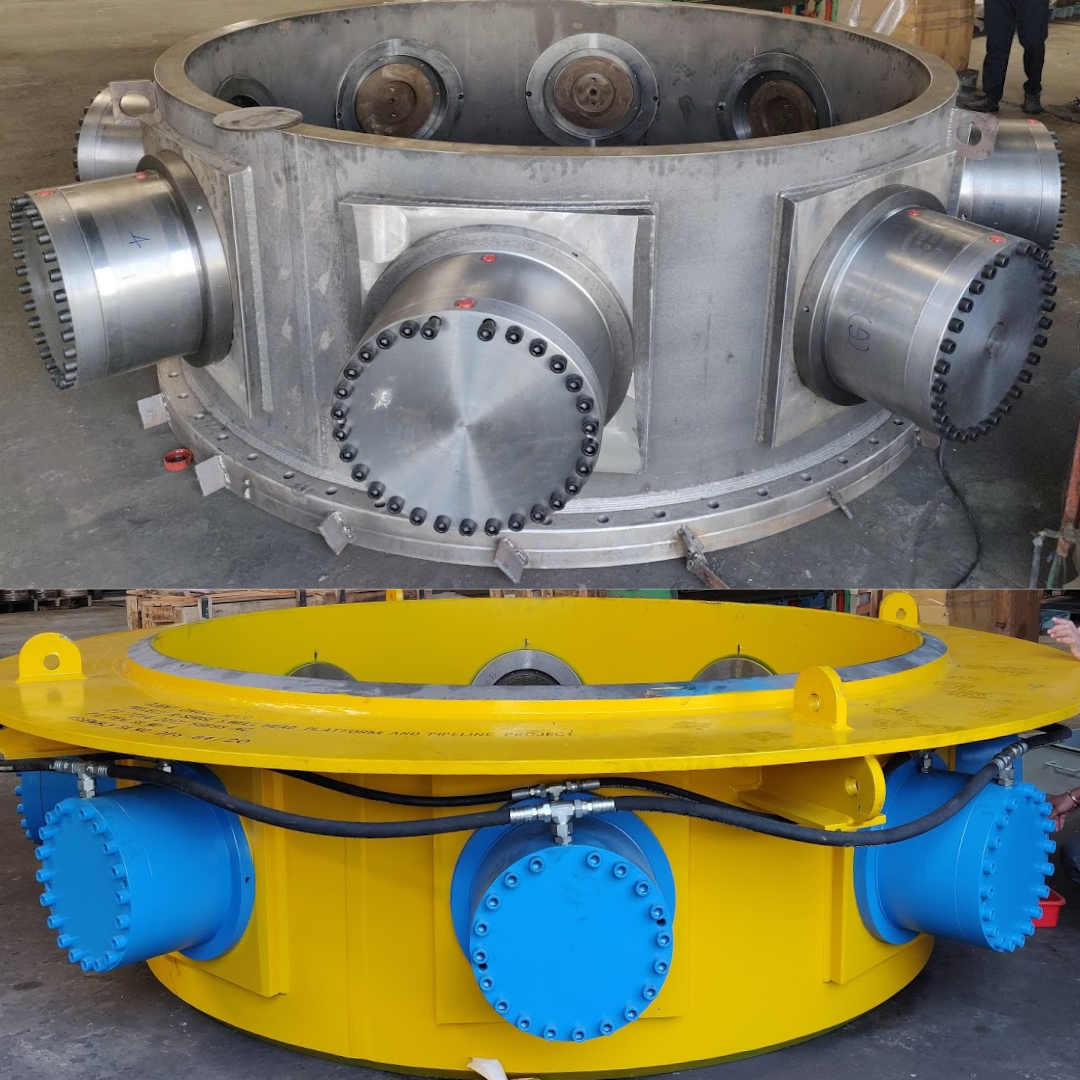

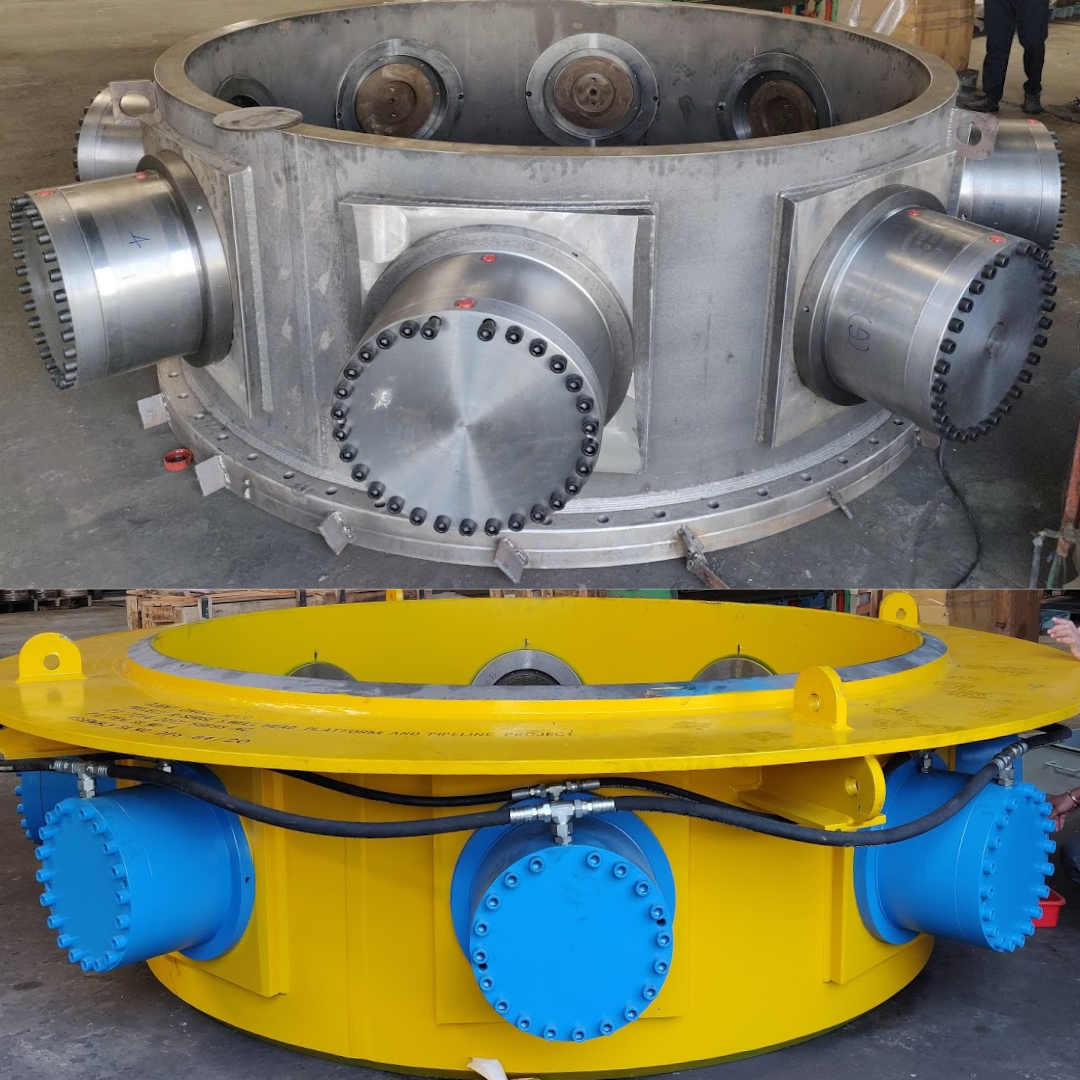

Our company, Office for Control and Civil Construction, in collaboration with Hi-Tech 94, is developing and patenting an innovative product for the hydraulic hammer market, tailored to different models. This partnership enables the development of top-quality solutions that enhance efficiency and reliability in the construction industry.

Hi-Tech Engineers has a dedicated team of experts with decades of experience, specializing in hydraulic and pneumatic systems. Their expertise allows the development of innovative solutions tailored to various industrial needs, market demands, and specific customer requirements.

These cylinders are designed for harsh marine and industrial environments, providing long-term reliability and high efficiency.

Specialized hydraulic cylinders that provide precise control and maximum durability in the steel and metallurgy industries.

Servo motors that provide high precision and control in manufacturing processes, with applications in the energy industry.

Hydraulic cylinders that ensure efficient operation of dam systems, maintaining stability and safety in water supply industries.

Components designed to work in harsh conditions in the foundry industry, enabling precise and safe operations.

Adjustable and durable hoses for a wide range of hydraulic applications.

Reliable fittings that ensure safe connections for hydraulic systems under high pressure.

High-quality filters that ensure oil cleanliness, extending equipment life and reducing maintenance costs.

Filtration units that provide constant oil quality control in hydraulic systems.

Universal replacement filters that fit a wide range of industrial systems.

This equipment enables precise mould production in the metal casting industry, increasing productivity and product quality.

Pneumatic hammers used in furnaces for precise shaping and material processing.

Units that provide centralized power and control for various hydraulic systems, improving efficiency and operational safety.

Hi-Tech Engineers provides innovative solutions in the hydraulic and pneumatic industries, allowing our company to offer products and systems that are reliable, efficient, and long-lasting. Their expertise in design and manufacturing, combined with their commitment to high industrial standards, makes them the ideal partner for all our projects, providing solutions that increase productivity, reduce costs, and ensure long-term equipment reliability.