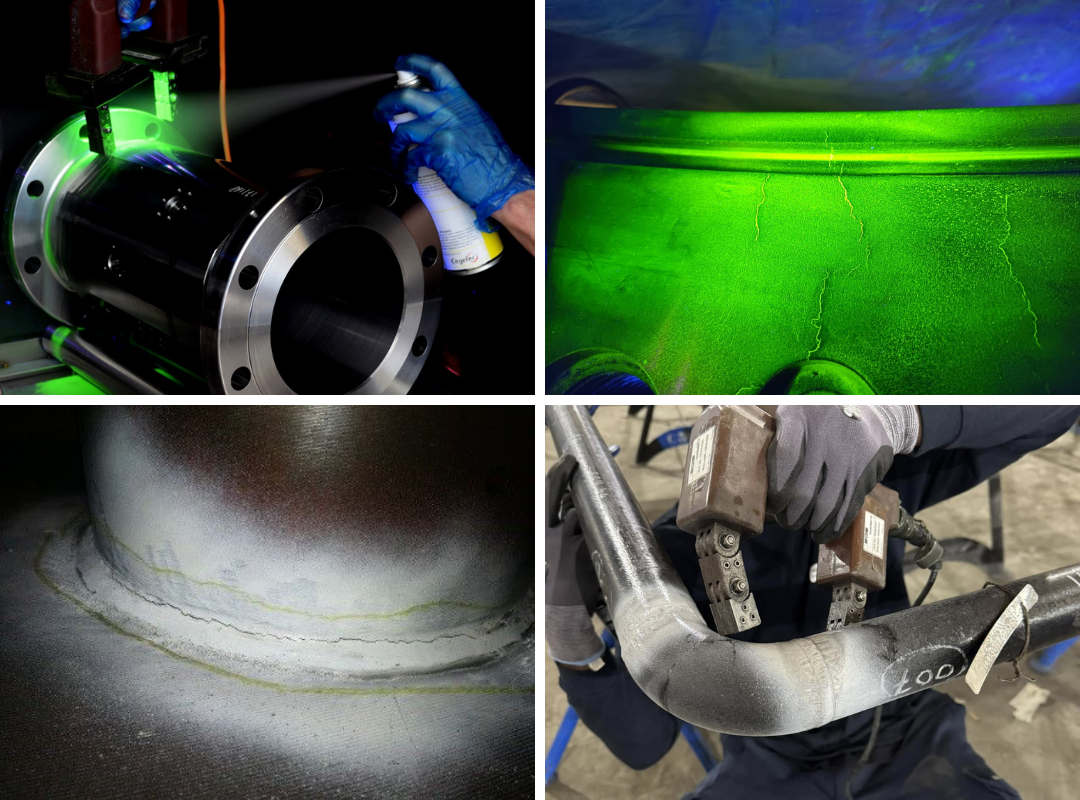

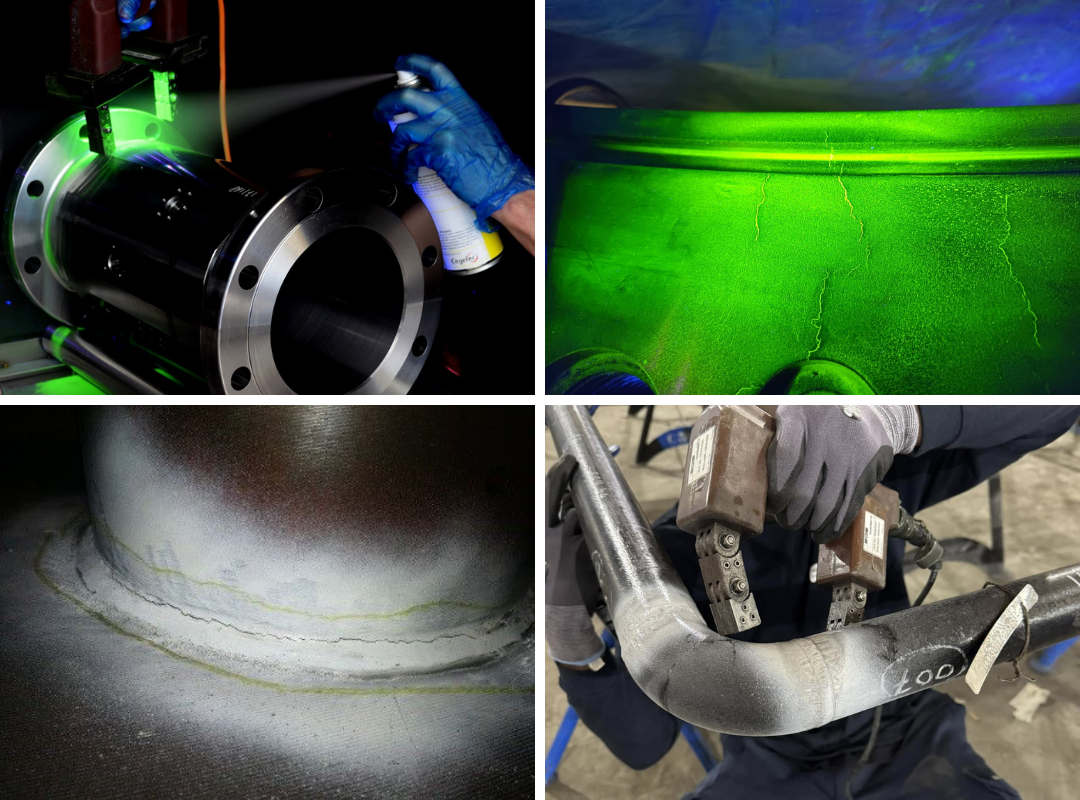

Non-destructive testing (NDT) is the evaluation of materials without causing damage to the specimen. It is frequently used in a product’s defect analysis, quality testing, and inspection inside or outside the testing lab. NDT methods are rapid, reliable, and standardized techniques used in offline batch inspections, in-line during manufacturing, or on-site inspection without disassembly.

We specialize in providing high-quality non-destructive testing (NDT) services to ensure the safety, reliability, and performance of your products. Our skilled experts perform precise and efficient inspections to detect potential defects, ensuring that your products meet the highest quality standards. By identifying and addressing issues early, we help reduce warranty costs, extend product lifespan, and improve customer satisfaction.

With advanced tools and techniques, we offer tailored NDT solutions across various industries, ensuring your equipment and materials remain safe and dependable.

Our team consists of highly skilled professionals certified to Level 2 and Level 3. Our experts hold multisector certificates in compliance with EN standard (EN ISO 9712) and ASNT (SNT-TC-1A), issued by the accredited certification body Sector Cert GmbH from Germany and American society for nondestructive testing.

Our certifications and experience ensure reliable, high-quality testing for a wide range of industries and applications.

Alos we provide high quality training, certification and NDT procedures according to EN and ASNT standard.